Hard metals can be difficult to work with, which is why electrical discharge machining is often known as the best process to use when dealing with complex shapes in hard metals.

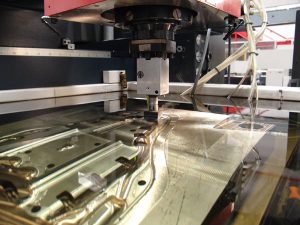

Electrical discharge machining (EDM) is also referred to as spark eroding, wire burning and wire erosion. An EDM machine can be utilized when trying to obtain a desirable shape in hard metals by using sparks (electrical discharges).

Using the thermal process of an EDM machine can remove material from hard metal by using a series of rapidly reoccurring discharges between electronics. It is always important to be safe and pay close attention when using EDM machines, but it will make the process of dealing with hard metals much more efficient.

Using the thermal process of an EDM machine can remove material from hard metal by using a series of rapidly reoccurring discharges between electronics. It is always important to be safe and pay close attention when using EDM machines, but it will make the process of dealing with hard metals much more efficient.

EDM machines work so well with hard metals because it can cut sophisticated shapes in pre-harden metal without having to use heat to soften then re-harden the metal. Traditional techniques usually don’t work as well with hard metals because they are group of materials with extreme hardness and have a high wear resistance.

For high levels of productivity, EDM machines can provide accuracy, durability and precision. Many of these machines are user-friendly and come with high performance capabilities at a reasonable cost. The thermal process of EDM has been used to work on heavy metals for over 50 years and now it is getting even better by adding EDM machines to the industry.